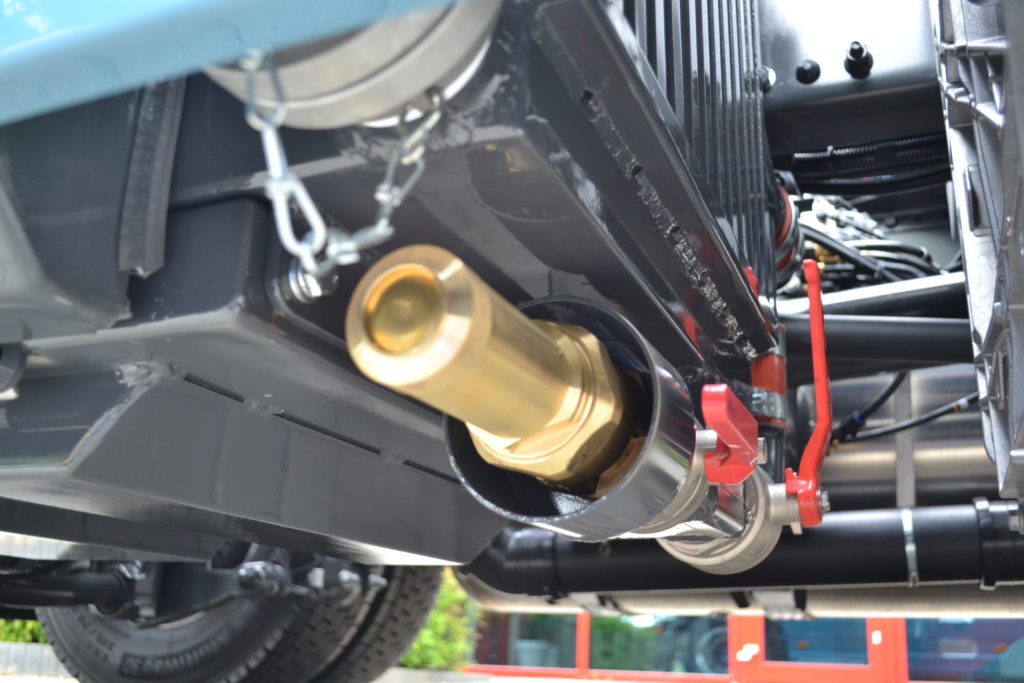

In an animal feed installation, a compressor with a large volume flow and high operating pressure is used in order to achieve faster unloading times. In addition, in case of animal feed installations, it is possible to place a swivel joint in front of the dish. By placing a swivel joint, a compressor tube can permanently remain connected to the trailer.

Animal feed installations

Advantages of using a compressor for feed

- The compressor installation’s low sound level enables a longer operation per day.

- Because of the strong pulsating operation of a screw compressor, a product with a high fat content sticking together occurs significantly less frequent.

- The installation can be used flexibly for both high and low pressure unloading systems.

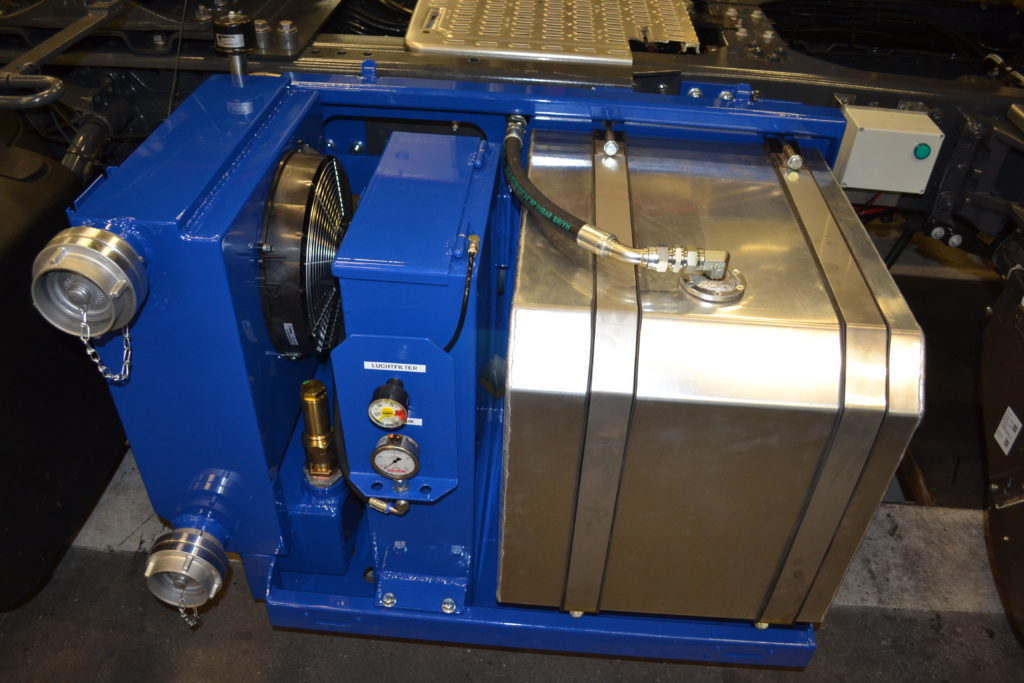

- The installation is equipped with an air pressure cooler. A lower air temperature equals less thermal stress on the seals and hoses. Furthermore it prevents damages to the product as a result of an increase in temperature.

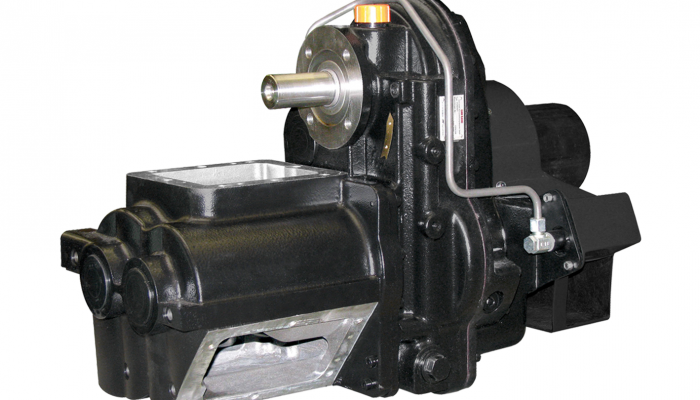

Compressor

Our assortment contains various compressors that are highly suitable for unloading animal feed. The compressor that is most suitable for you depends on a number of factors. The type of trailer and the unloading pressure are of importance, for example. The location likewise influences the choice of compressor, since the unloading distance and the type of piping at the location are aspects that should be taken into account.

Silencers and filter

The RTI aluminium pulsation silencer is constructed based on the volume size and is equipped with a (steered) pressure relief valve and a built in non-return valve.

The aluminium filter unit is equipped with a high-quality and moisture resistant 5 μm RTI/Mira air filter/intake silencer.

By applying these parts in combination with aluminium pipes and a cooling installation, the installation will meet all requirements set by the chemical and food industry.

OPTIONS

The RTI installation can be tailored to your wishes with several options and additions.

Toolbox

We also produce and mount toolboxes made of aluminium or stainless steel. The direct driven installation can be made with an integrated toolbox. The toolbox will be custom-made and can be equipped with shelves and/or drawers. Especially for semi-trailer trucks with side-skirts that hinge out, the toolbox can be equipped with doors hinged at the bottom.

High air intake

The compressor installation can be equipped with a high air intake developed by RTI. Air is drawn in at the top of the driver’s cab, this prevents the intake of dust and exhaust gasses.

The intake of cleaner and cooler air will increase the longevity of the air filter. The high air intake can also be adjusted to the Mobil Plastics requirements for air intake. (MP requirements state that air should be drawn in at the top of the driver’s cab.)

Air outlets

The standard outlets of an RTI installation are placed at the front of the cooler, the cold outlet at the top and the warm outlet at the bottom. You can also choose to have the outlets changed according to your wishes.

Compressed air cooler

To save space the compressed air cooler can be installed at the bottom of the installation. The minimum space required to mount the installation is 850 mm.

Hydraulic tank

For direct driven installations it is possible to integrate the hydraulic tank within the installation. The tank has a net content of 190 – 250 litres depending on your wishes.

Other options

Flexible use of the installation can be attained by the following options:

- a blow-off silencer

- an extra pressure relief valve (high/low pressure)

- cold and warm air mixing

- a combination of the above

COMPRESSORS

GHH CS1200

| Type | GHH CS1200 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 731-1141 |

| Flow rate (m3/h) at 2 bar | 714-1126 |

| Flow rate (m3/h) at 2.5 bar | 697-1110 |

| Speed range (rpm) | 1200-1800 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 39,3-61,9 kW |

| Minimum mounting space | 60 cm |

| Soundlevel installation | 85 dBA |

| Dimensions installation | 55x75x75 cm |

CVS SKL1200

| Type | CVS SKL1200 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 537-1096 |

| Flow rate (m3/h) at 2 bar | 504-1070 |

| Flow rate (m3/h) at 2.5 bar | 481-1045 |

| Speed range (rpm) | 1000 – 1800 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 31-57 kW |

| Minimum mounting space | 60 cm |

| Soundlevel installation | 85 dBA |

| Dimensions installation | 55x75x75 cm |

CVS SiloKing 1100LS

| Type | CVS SiloKing 1100LS |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 505-995 |

| Flow rate (m3/h) at 2 bar | 490-980 |

| Flow rate (m3/h) at 2.5 bar | 475-962 |

| Speed range (rpm) | 1630-2930 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 28,5-52,5 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA (stationary unit 75 dBA) |

| Dimensions installation | 95x75x75 cm |

CVS SiloKing 1500

| Type | CVS SiloKing 1500 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 710-1580 |

| Flow rate (m3/h) at 2 bar | 690-1560 |

| Flow rate (m3/h) at 2.5 bar | 670-1540 |

| Speed range (rpm) | 1000-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 41-85 kW |

| Minimum mounting space | 120 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 105x75x75 cm |

ALFONS HAAR CMAX3

| Type | Alfons Haar Cmax3 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 625-1180 |

| Flow rate (m3/h) at 2 bar | 610-1070 |

| Flow rate (m3/h) at 2.5 bar | 605-1055 |

| Speed range (rpm) | 1200-2100 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 38-65 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA (stationary unit 75 dBA) |

| Dimensions installation | 95x75x75 cm |