Powerband drive

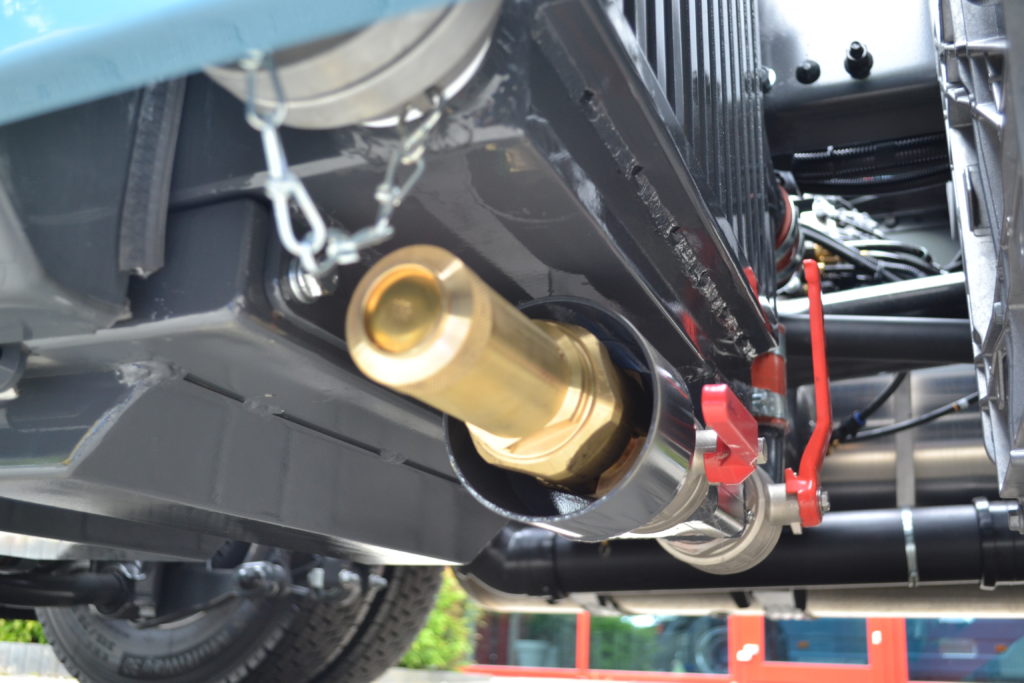

In order to transfer a lager capacity and to prevent the V-belt jumping off the pulley as a result of too little suspense, the installation can be equipped with powerband (special V-belt) drive in combination with an automatic tightening system. The automatic tightening system is a rubber element which will keep the powerband in suspense at all times and reduces the vibration in the transmission.